This week I tried to replicate the joints Ben showed us on class.

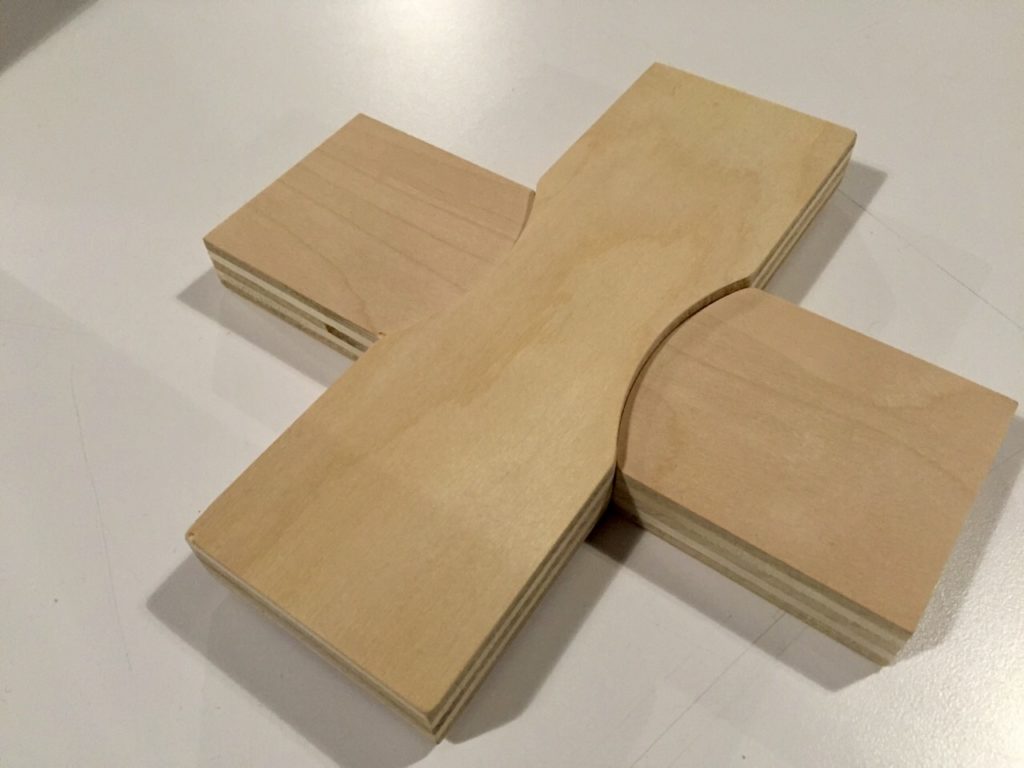

At last I got the result.

Even though it looks simple, it still turned out to be tricky.

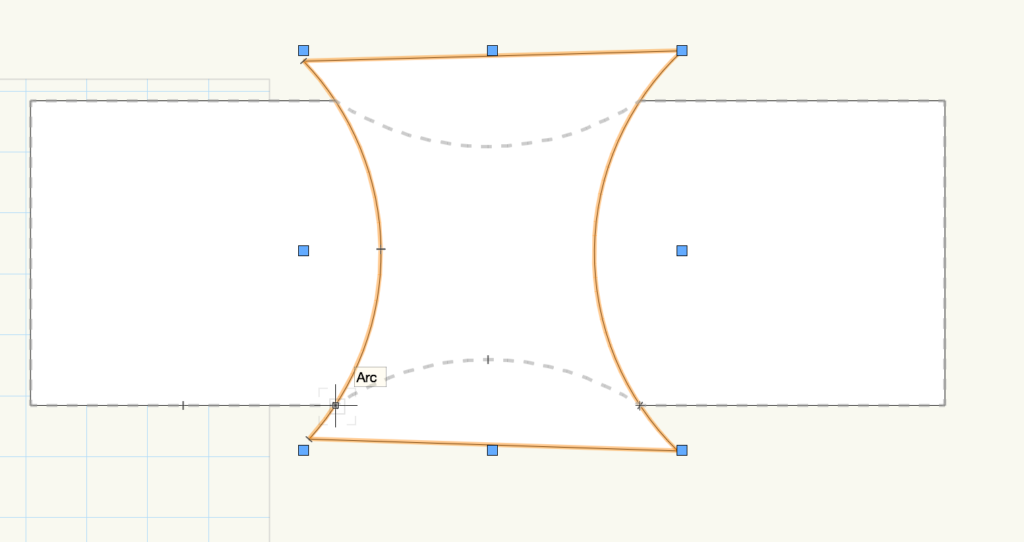

This is the design file I used. Though I was told to make some tolerance, I have no idea how much should I leave…so I just make the inner and outer size exactly the same.

This is how it looks like: inner pocketing and outer contour.

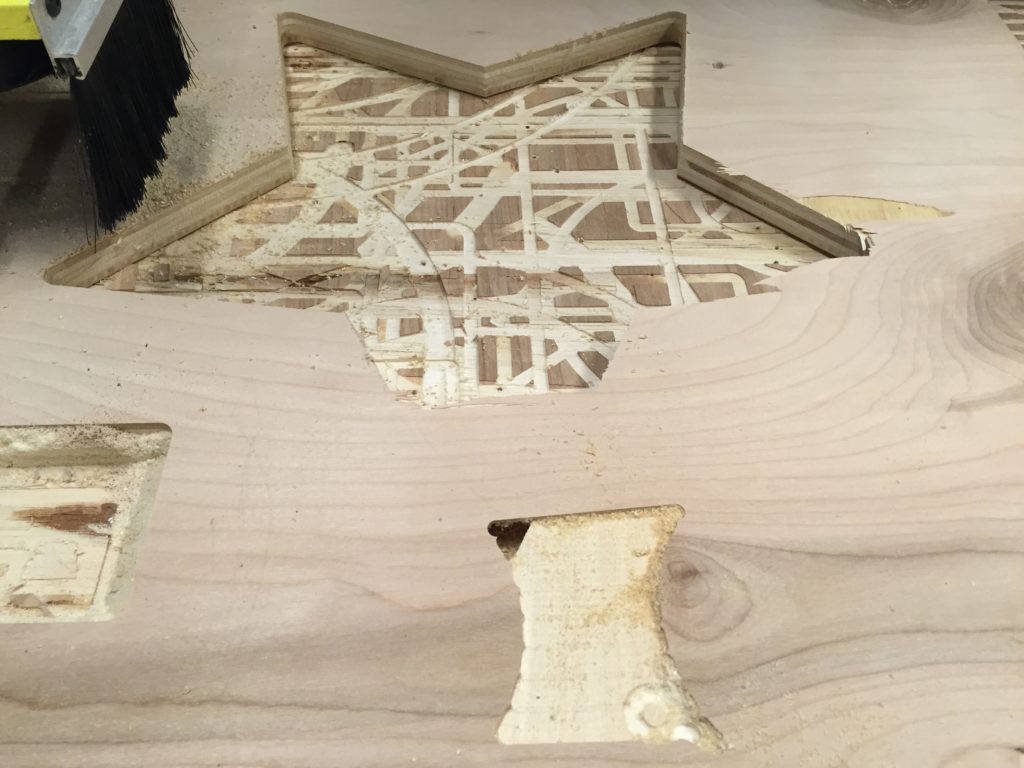

I measured the wood as around 0.73″ – 0.74″ thick so I make the contour cutout depth to be 0.74″. And the pocketing I thought I take some value as 0.36″, which turned out to be a lot.

So it doesn’t seem to be perfectly fit with each other.

Also, watch out for some already cut pieces…Haven’t realized there was a hole below so I had to cut again.

Also by making no tolerance I had to sand the two pieces really hard to make them fit. But anyway it seems the CNC is precise enough so I only need to make a very tiny tolerance to get them comfortable.

I’m confident I can make it better the next time.